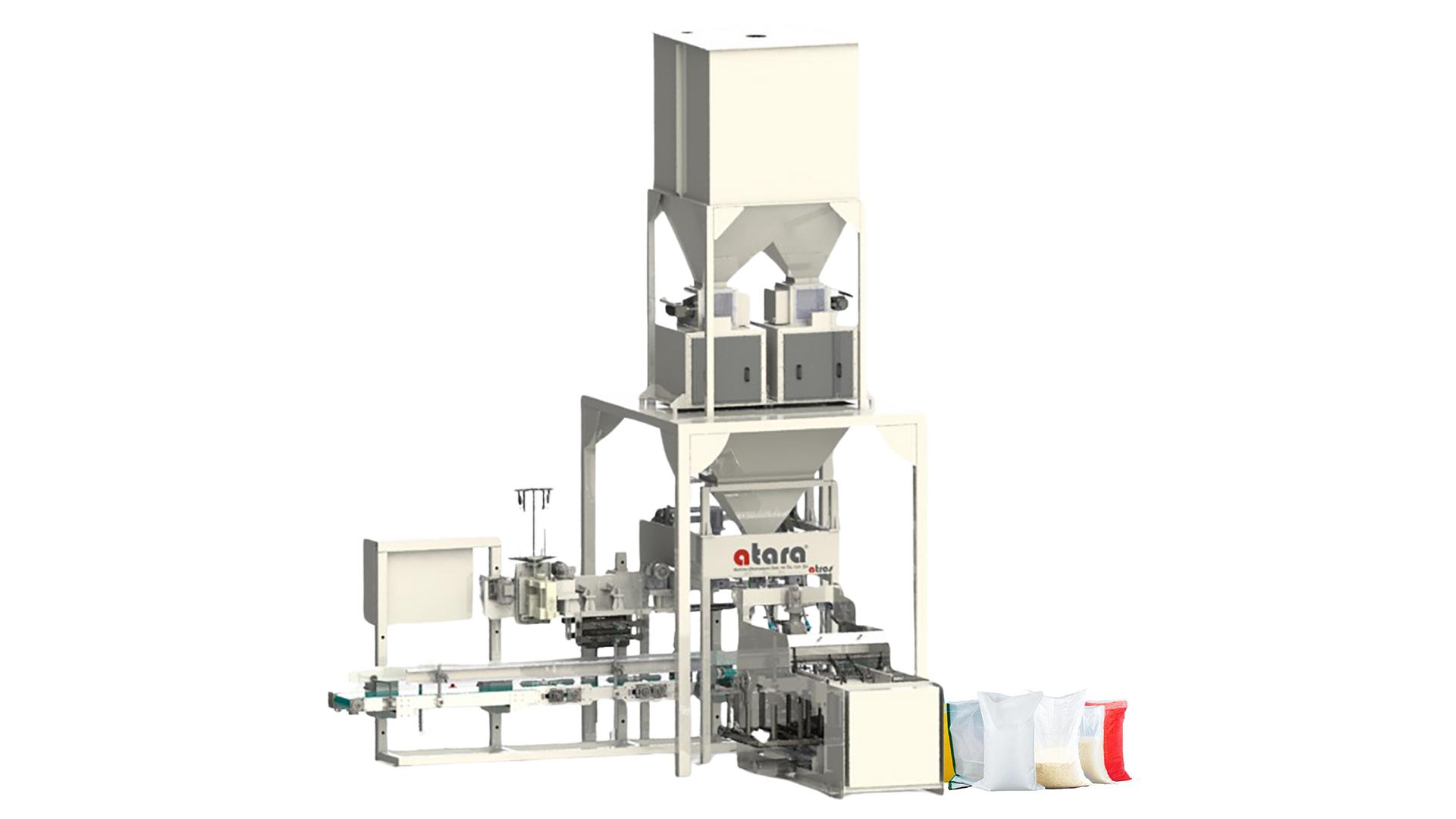

BıgBag Packaging (Filling) Machine

ATR-BB BigBag Packaging Machine

ATR-BB BigBag Packaging Machine is a high capacity manual filling system developed for precise and safe packaging of (flour, feed, chemical powders, grain derivatives, etc.). High hygiene, robust construction and industrial durability.

Highlighted Features

- Easy calibration with PLC controlled system

- Epoxy paint in compliance with food regulations

- Precise weighing with stainless steel loadcell

- Different product filling settings depending on the prescription

- Maximum operator safety with emergency stop button

- Hygienic filling with sealed structure without gasket

- 30 tons/hour capacity with 1 m³ shroud

- Low air and energy consumption

- Optional: CR-Ni 304 stainless body option

Application Areas:

- Flour and semolina production facilities

- Feed factories

- Chemical powder and granular products

- Packaging of agricultural and food raw materials

Why ATR-BB BigBag Packaging Machine?

- Precise weighing up to 1000 kg

- Easy operation, low maintenance

- Durable and long-lasting construction

- Flexible system compatible with different products

- Easy integration into industrial lines

| Packaged Product Type | Feed |

| Density | 0,55 g/cm³ |

| Weighing Accuracy | ±%0.5 |

| Platter Capacity | 1 m³ |

| System Pressure | 6-8 bar |

| Power Supply | 220 V AC / 50 Hz |

| Electricity Consumption | 1 kW/h |

| Weight | 3240 KG |

| Air Supply |

~ 0,6 m³/h |

Similar products

Büyükkayacık O.S.B. Mahallesi 513 Nolu Sokak No: 9 Selçuklu/KONYA - TÜRKİYE

+90 (332) 345 02 06

Atara | Makine & Otomasyon All rights reserved. NadaHub