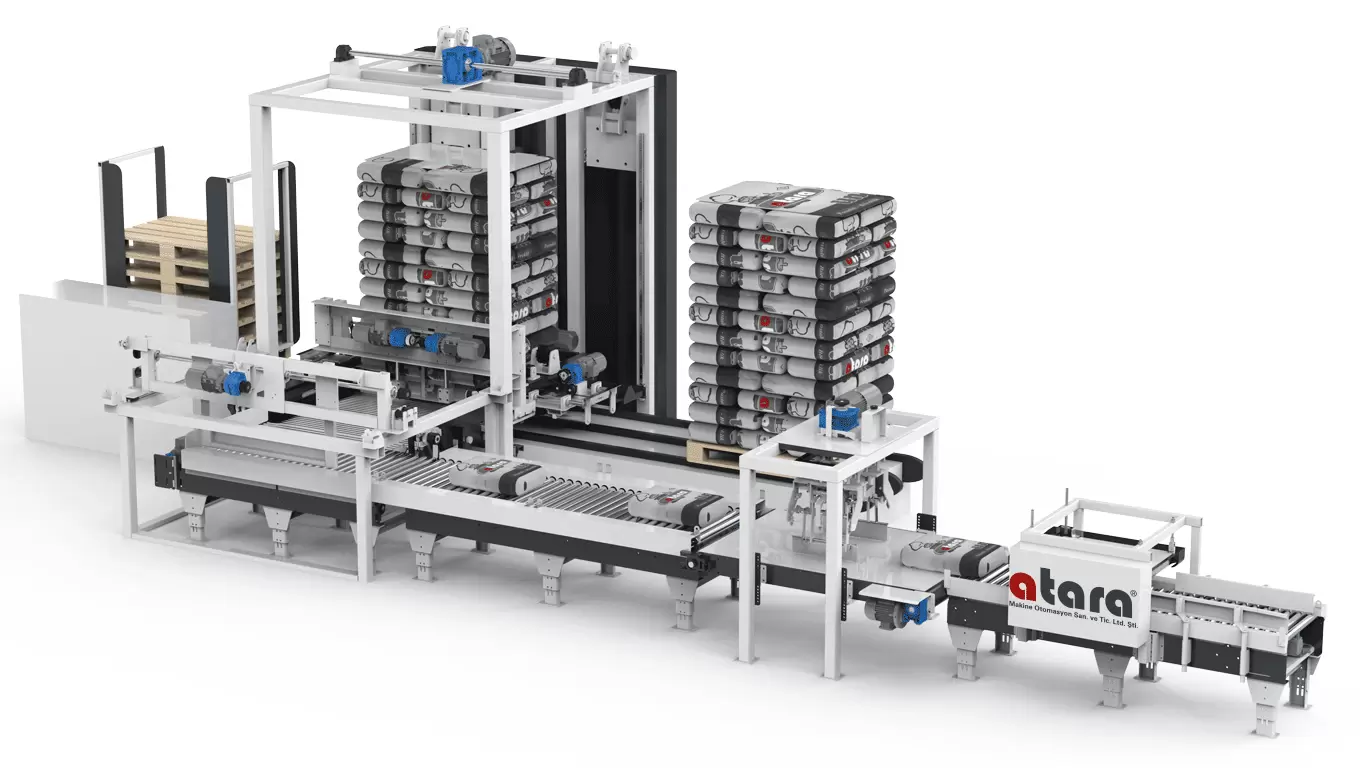

Palletizing Unit - Automated Palletizing Solutions

A palletizing unit is an automated system that ensures the orderly and safe stacking of packaged products on pallets at the final stage of the production line. These machines operate at high speed, reducing labor costs and increasing production efficiency

Highlighted Features

- Flexible Design: Modular structure that can adapt to different product types and packaging.

- High Capacity: High production speeds with pallet stacking capacity.

- Advanced Control System: Precise and reliable operation with PLC based automation.

- Compact Structure: Optimized design for efficient use even in limited spaces.

- Integrated Systems: Integrated solutions such as empty pallet feeding, interlayer placement and stretch wrapping.

Application Areas:

- Food and beverage industry

- Chemicals and pharmaceuticals

- Agriculture and fertilizer, powder, granular, feed production facilities

- Construction chemicals and building materials

Why Palletizing Unit?

- Labor Efficiency: Up to 80% labor savings compared to manual palletizing.

- Production Speed: Increases production line efficiency with continuous and fast palletizing.

- Safety: Protects operators from heavy lifting operations.

- Space Saving: Saves space in the facility with its compact design.

- Low Maintenance Cost: Reduces maintenance costs with durable and long-lasting components.

| Packaged Product Type |

Flour, feed, pulses, fertilizer etc. |

| System Pressure | 6-8 bar |

| Power Supply | 380 V AC / 50 Hz |

| Electricity Consumption | 22 kW/h |

| Protection Class | IP54 |

| Weight | 6000 KG |

| Air Supply | ~ 3 m³/h |

Similar products

Büyükkayacık O.S.B. Mahallesi 513 Nolu Sokak No: 9 Selçuklu/KONYA - TÜRKİYE

+90 (332) 345 02 06

Atara | Makine & Otomasyon All rights reserved. NadaHub